Welcome to China Hard Materials Parts. Thank you for visiting!

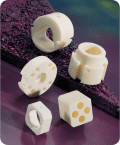

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Key properties of this material include thermal shock resistance as well as fracture toughness. These coupled with high temperature strength and wear resistance even under oxidizing conditions make silicon nitride an excellent candidate for IC engine and turbine applications.

Silicon nitride is difficult to produce as a bulk material in the preferred hot press sintering method as the components dissociate over 1850C. Lower temperature methods have been developed using sintering aids or by spark sintering. Results in every case though do drive the cost of this material above most technical ceramics.

The sintered material can be further fabricated to precise features and tolerance by diamond grinding. Some of the very properties of silicon nitride that make it attractive for application make it likewise more difficult to grind than other technical ceramics. Grinding is most productive when the material submits to micro impacts and is less resistant to wear in general. Grinding silicon nitride therefore forces lower material removal rates than with alumina for example which results in higher fabrication cost.

Silicon nitride does provide excellent performance for specific applications like turbochargers, rocket engines, ball bearings, and cutting tools for cast iron. Precision machined components are possible for many new applications as well based on the unique properties of this material. Such cases warrant careful analysis of design to minimize features requiring extensive machining. Cost can limit wider application but the unique property benefits to performance of key components can optimize project performance and make or break success.

*Click on a Property to see a comparison of up to 10 materials