Welcome to China Hard Materials Parts. Thank you for visiting!

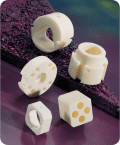

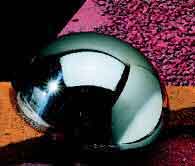

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Silicon Carbide is among the hardest of ceramics, and retains hardness and strength at elevated temperatures, which translates into among the best wear resistance also. Additionally, SiC has a high thermal conductivity, especially in the CVD (chemical vapor deposition) grade, which aids in thermal shock resistance. It is also half the weight of steel.

Based on this combination of hardness, resistance to wear, heat and corrosion, SiC is often specified for seal faces and high performance pump parts.

Reaction Bonded SiC has the lowest cost production technique with a course grain. It provides somewhat lower hardness and use temperature, but higher thermal conductivity.

Direct Sintered SiC is better grade than Reaction Bonded and is commonly specified for high temperature work.

CVD SiC (R) is a face centered cubic, polycrystalline form produced by chemical vapor deposition. This material is extremely pure, and is specified for it's excellent thermal conductivity approaching 300 W/mK. It is considerably more expensive to produce than the sintered or reaction bonded grades. (R) Rohm & Haas.

*Click on a Property to see a comparison of up to 10 materials