Welcome to China Hard Materials Parts. Thank you for visiting!

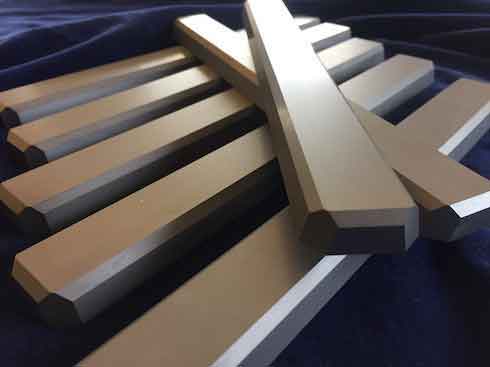

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Boron Carbide is a synthetic material that ranks in hardness behind only Cubic Boron Nitride and Diamond. It is the hardest material produced in tonnage quantities, although much is utilized in powder form for abrasive grinding and lapping applications and abrasive water jet cutting or as coatings for nuclear applications. The powder can be formed into basic shapes by pressing at temperatures exceeding 2000C.

In solid form, B4C exhibits very low density along with the highest of hardness and good wear resistance. Along with high elastic modulus, this combination provides superb energy absorption against ballistics especially when coupled with other materials like plastics. Low density appeals to personnel protective gear and airborne protection designers. Ballistic Armor has become a major application for B4C production in recent years.

Other applications include nozzles for high wear blasting and other ceramic tooling dies. Nuclear reactors depend on B4C properties of neutron absorption and chemical resistance in shielding applications and for control rods. Specialty abrasion and crash protection items have also been designed for aircraft that benefit from the hardness and low density of Boron Carbide.

As with many sintered technical ceramics, producers are able to machine the semi-fired or “green” form to rough dimension and also relatively easily add simple features like holes. During the high temperature final fire however, the green part shrinks significantly and it is not possible to hold to a tight tolerance. So if precision parts are required, a post-fire machining is necessary by use of diamond grinding.

China Hard Materials Parts employs diamond grinding technology throughout our shop to fabricate precision parts from all ceramic materials including B4C. However. it is an exceptionally difficult material to machine and we usually recommend engineers also consider more common ceramics like aluminum oxide due to better raw material availability and easier processing.

*Click on a Property to see a comparison of up to 10 materials