Welcome to China Hard Materials Parts. Thank you for visiting!

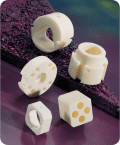

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Zirconia PSZ are cream colored blends with approximately 10% MgO and are high in toughness, retaining this property to elevated temperatures. They are somewhat lower in cost but have larger grain structure.

Zirconia is best known among ceramics as being both hard and fracture-tough at room temperature. Additionally, its fine (sub-micron) grain size enablesexcellent surface finishes and the ability to hold a sharp edge.

Although it retains many properties including corrosion resistance at extremely high temperatures, zirconia does exhibit structural changes that may limit its use to perhaps only 500 °C. It also becomes electrically conductive as this temperature is approached.

Zirconia is commonly blended with either MgO, CaO, or Yttria as a stabilizer in order to facilitate transformation toughening. This induces a partial cubic crystal structure instead of fully tetragonal during initial firing, which remains metastable during cooling. Upon impact, the tetragonal precipitates undergo a stress induced phase transformation near an advancing crack tip. This action expands the structure as it absorbs a great deal of energy, and is the cause of the high toughness of this material. Reforming also occurs dramatically with elevated temperature and this negatively affects strength along with 3-7% dimensional expansion. The amount of tetragonal can be controlled by additions of the blends above to balance toughness against loss of strength.

Cubic Zirconia: This single crystal optically clear form of ZrO2 has a relatively low fracture toughness and strength, but very high thermal shock resistance.

Zirconia TZP: Yttria blends of approximately 3% are called tetragonal zirconia polycrystal (TZP) and have the finest grain size. These grades exhibit the highest toughness at room temperature, because they are nearly 100% tetragonal, but this degrades severely between 200 and 500 °C as these irreversible crystal transformations also cause dimensional change.

*Click on a Property to see a comparison of up to 10 materials