Welcome to China Hard Materials Parts. Thank you for visiting!

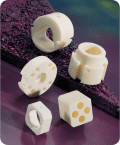

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Alumina (Al2O3) is one of the most widely specified, general-purpose technical ceramics. All aluminas are very hard and wear resistant, with high compressive strength even against extreme temperatures and corrosive environments. Aluminas are also excellent electrical insulators and are gas tight.

Alumina is produced by firing a tightly packed powder form of Al2O3 which includes some binder material. Commercially available grades range from 90% up to 99.95% with the higher purity generating somewhat higher hardness. It is possible to machine alumina using diamond grinding techniques. Polishing is also possible, with the degree attainable affected by alumina grain size and production technique, whether pressed or extruded.

90%-97% - Best suited for metalizing (metal deposition which allows brazing) because of large grain structure.

98%-99.95% - Common range for isostatically pressed grades, with extruded shapes also available at low cost.

As-fired tolerances are generally only possible within a few percent of dimension. Extremely tight tolerances are attainable, but only by precision machining the fired part using diamond grinding techniques. This adds considerable cost, but tolerances to millionths of an inch are possible, and are often cost effective due to the extraordinary stability and durability of the finished piece.

Additional options include blends of zirconia with alumina and silicon nitride with alumina. The result is a performance combination that is tougher than alumina alone, but with improved hardness, strength and thermal properties compared to these other materials, especially at elevated temperature.

*Click on a Property to see a comparison of up to 10 materials