Welcome to China Hard Materials Parts. Thank you for visiting!

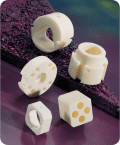

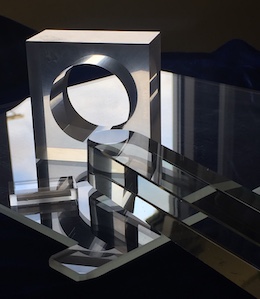

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Borosilicate glass is composed of 80.6% SiO2, 12.6% NaO2, 2.2% Al2O3 and traces of other key materials. This glass was formulated to achieve excellent thermal shock resistance and high-temperature resistance. Additional benefits include low thermal expansion and high resistance to chemical attack, as well as good transmission from UV to IR.

Precision parts can be fabricated from this transparent material, and it is therefore specified for LCD displays, telescope mirrors, sensors for electronics, and multiple uses within optical, MEMS, nuclear energy, and other precision-engineered applications.

PYREX was the brand name created by Corning many years ago for their borosilicate glass. It is well known from cookware that stood up to oven temperatures and rapid cooling during kitchen handling. PYREX was also often used for laboratory equipment, as well as for other applications. Corning eventually licensed both the PYREX and pyrex logos to other companies. PYREX is claimed to be a borosilicate glass, while pyrex is claimed to be a soda-lime glass product, although both are marketed for cookware. The borosilicate version presumably has greater resistance to thermal shock.

Corning 7740 is the current standard for borosilicate glass produced by the company. This glass is produced in blocks as opposed to sheets, and must therefore be cut into smaller pieces for eventual use. For this reason, designers requiring larger-sized precision glass parts will often specify 7740 as the material.

Schott 8330 is the current borosilicate glass produced by the Schott Company. This glass, also known as Borofloat 33, is produced in sheets by the float glass method. Depending on the final application, standard thickness may be useful as-is, requiring only cutting to size. A waterjet method may be used on glass if tolerances are not considered critical. But a diamond grinding process is required to achieve the tightest tolerances.

Simple cutting creates a “chippy” edge, so precision parts are generally cut oversized and then ground back to the required dimension to clean up chips. Chamfers are also specified to minimize future problems from handling the sharp edges. Ground surfaces can be flame-polished, although this lowers the dimensional accuracy of the part and necessitates a subsequent anneal. Ground surfaces can also be chemo-mechanically processed to achieve high levels of polish. Generally these operations are performed one surface at a time and are therefore a cost driver that needs to be carefully considered.

Since 1947, China Hard Materials Parts has had many years’ experience sourcing borosilicate glass raw material and then fabricating and polishing precision pieces to customer specifications. Borosilicate glass is readily available in multiple sizes of tubing in standard one meter length. This can be a useful and economic start point for further machining. Otherwise, 7740 or Borofloat materials as described, are usually specified for precision component fabrication.

*Click on a Property to see a comparison of up to 10 materials