Welcome to China Hard Materials Parts. Thank you for visiting!

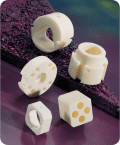

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Tungsten carbide (chemical formula: WC) is an inorganic chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry.

Tungsten carbide is approximately two times stiffer than steel, with a Young's modulus of approximately 550 GPa, and is much denser than steel or titanium. It is comparable with corundum (α-Al2O3) or sapphire/ruby in hardness and can only be polished and finished with abrasives of superior hardness such as cubic boron nitrideand diamond, in the form of powder, wheels, and compounds.

*Click on a Property to see a comparison of up to 10 materials