Welcome to China Hard Materials Parts. Thank you for visiting!

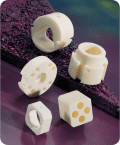

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Silicon Carbide is industrially produced by sintering, reaction bonding, crystal growth, and chemical vapor deposition (CVD).

Silicon carbide offers low density and high stiffness, as well as extreme hardness and wear resistance. The CVD material can be produced with such low electrical resistance (around one ohm cm) that it can be considered a reasonable conductor of electricity. Although fabrication of precision parts from blanks of CVD SiC must be completed via diamond grinding technologies, this electrical property allows fabrication of fine features by use of EDM methods, which can be useful for generating tiny holes with high aspect ratios.

Another interesting feature of silicon carbides is their relatively high thermal conductivity. Here again, the CVD material excels by achieving at least 150 W/mK, which exceeds that of common steels and cast iron. Thermal conductivity does decrease with temperature and must be considered carefully against specific applications.

CVD silicon carbide has been used for many years in semiconductor processing applications, where excellent thermal shock resistance and resistance to erosion by high-energy plasmas are required. CVD properties can benefit all types of applications, including electrodes and sputter targets; components like susceptors, gas distribution plates, chucks, heaters; and edge rings or any application that requires electrical conductivity, wear resistance, and thermal shock resistance.

China Hard Materials Parts, Inc. has many years of experience fabricating precision parts from this material. Our technology consists of diamond grinding of CVD silicon carbide in its extremely hard available state. Normally China Hard Materials Parts will source materials from the most appropriate producer and then fabricate to meet our customer’s most stringent dimensional requirements.

*Click on a Property to see a comparison of up to 10 materials