Welcome to China Hard Materials Parts. Thank you for visiting!

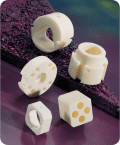

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Sapphire is an anisotropic, rhombohedral crystal form of Aluminum Oxide.

Anisotropic single crystal materials exhibit some properties such as thermal expansion and hardness which vary significantly by orientation. For most applications this is unimportant, however it should be considered. Since 1947, China Hard Materials Parts has had experience with this material and we can provide considerable insight as to how orientation might affect your application.

Sapphire is also “birefringent” which is an optical refractive property that offsets wave transmission up to 0.8% at right angles to the optic axis. Birefringence is eliminated along the optic or C-axis of the crystal. Therefore, for certain optical applications, C-axis sapphire should be specified to avoid this effect.

Industrial sapphire is created by melting aluminum oxide (Al2O3) at 2040°C and then encouraging crystal growth with a seed and careful control of the environment. Growers have developed several unique methods for growth, with varying levels of resultant quality, size, and cost. The EFG or Stephanov methods allow the directed growth of shapes like ribbon, or even tubes, however there are many limitations to what can be done. The Czochralski, HEM, or Kiropolous methods allow the highest optical quality sapphire, but the result is a rod like “blob” of crystal called a boule, that must be entirely machined into useable shapes and sizes.

Sapphire and Ruby are actually the same material with small amounts of chromium (typically ≤ 0.05% by weight) added which affects color and optical properties, while not affecting mechanical, thermal and electrical properties significantly.

*Click on a Property to see a comparison of up to 10 materials