Welcome to China Hard Materials Parts. Thank you for visiting!

Since 1947, we have been a precision machining and polishing fabricator of parts from all technical ceramics, sapphire, glass and quartz. We machine these materials to very precise tolerances (many times measured in millionths of an inch) for dimension, flatness, wedge and roundness or cylindricity. Our customers typically have a critical application that requires extremely tight tolerances in ultra-hard materials. We also have the capability to grind and polish spherical radius parts in a variety of hard materials, both inside and outside diameters, to optical requirements.

Please feel free to navigate to other pages within our site to see more information on all of our high precision machining services, materials and capabilities. If you would like more information please click here to send a request, or visit our Frequently Asked Questions page.

Macor(R) is a machinable glass ceramic which withstands high temperatures while providing tight tolerance capability.

Macor(R) is a great compromise material when contemplating the need for true ceramics. This trademarked material is a product of Corning Glass Company that was formulated to provide features of a silica glass, but also be readily machinable. Solid white, this mica glass ceramic material is made up of roughly 46% silica, 17% MgO, 16% Al2O3, 10% K2O, 7% B2O3 and 4% F.

Like Fused Quartz, Macor is stable up to almost 1000C with very low thermal expansion or thermal or electrical conductivity that beats most high performance plastics. It is non-porous, exhibits good technical strength, and doesn’t outgas at high temperatures. But the special characteristic for this type “ceramic” material is that it can be machined by conventional HSS single point cutting tools although carbide tools are a better choice for longer wear.

Drilling chips and grinding swarf will be as hard as the Macor and will therefore subject machine ways to higher abrasion over time. As when machining any ceramic, use of high volumes of coolant is also recommended. The ability to machine a “ceramic” part with conventional tools might allow an engineer’s in-house shop to fabricate development prototypes with quickest turnaround.

Depending on the application, Macor might be totally adequate to the task for final production as well. But if hardness at higher working temperature is necessary, ceramics like Aluminum Oxide or Silicon Carbide or Zirconia will be better choices.

Corning produces and makes available Macor with a size range limited to 12” maximum dimension. Stocking distributors offer standard raw material sizes in plates, bars and rods within this limitation.

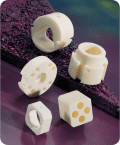

China Hard Materials Parts has fabricated precision parts from Macor for many years. Our normal processing involves diamond grinding and is used to achieve many features in Macor since this method and our sophisticated machines can achieve tighter tolerance than most single point cutting. Some features like small holes with high aspect ratio are best generated with our conventional drilling machines. All China Hard Materials Parts equipment is designed for processing the hardest of materials, and our machinists have evolved special techniques for efficient production.

Macor has been useful for cutting edge applications in Aerospace, Semiconductor, Medical and Laboratory fields. Its stability is useful for Fixtures, and non-gassing property for Ultra High Vacuum environments.

Other Glass Ceramics :

Zerodur(R) and

Corning ULE(R)

*Click on a Property to see a comparison of up to 10 materials